Optimizer

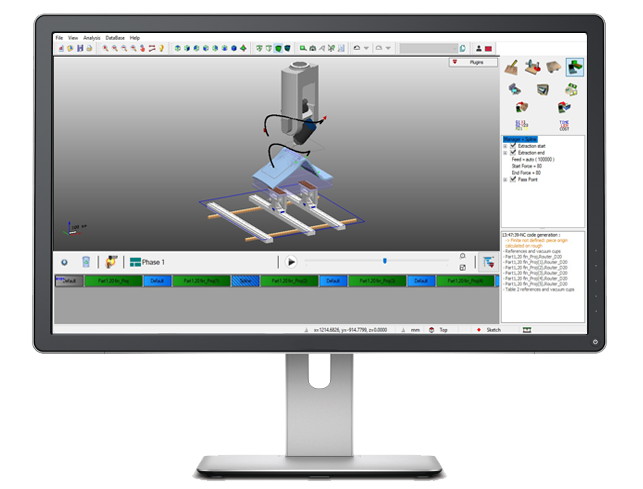

The DDX Optimizer is an optional module of our software that has as main objective the optimization of the joints between the machining and the verification of the absence of collisions in the execution of such movements. Specifically, the DDX Optimizer offers:

- Simulation of machining and junctions with display of the active head and table elements;

- Modification and customisation of the junctions automatically generated by the software;

- Various ways of modifying the junctions, which can be selected according to requirements;

- Calculation of automatisms that make it possible to facilitate, or sometimes replace, user intervention;

- Collision verification of junction movements and report to the user;

- simple and effective user interface, which allows you to have full control of what you want to achieve on the machine and feedback on any critical issues;

- Mode of action without user intervention, which tries to apply optimizations where possible, verifying the feasibility and absence of collisions;

- Estimation of processing times and joints;

- Multiple head management and mutual collision control;

- inverse-time generation, to have total control over the heads movement dynamics.

With the DDX Optimizer you obtain a considerable time saving, generating movements as much as possible tangent, not too wide and without collision, avoiding the classic junctions, characterized by large safety distances and axis unwinding.

Optimizer

The DDX Optimizer is an optional module of our software that has as main objective the optimization of the joints between the machining and the verification of the absence of collisions in the execution of such movements. Specifically, the DDX Optimizer offers:

- Simulation of machining and junctions with display of the active head and table elements;

- Modification and customisation of the junctions automatically generated by the software;

- Various ways of modifying the junctions, which can be selected according to requirements;

- Calculation of automatisms that make it possible to facilitate, or sometimes replace, user intervention;

- Collision verification of junction movements and report to the user;

- simple and effective user interface, which allows you to have full control of what you want to achieve on the machine and feedback on any critical issues;

- Mode of action without user intervention, which tries to apply optimizations where possible, verifying the feasibility and absence of collisions;

- Estimation of processing times and joints;

- Multiple head management and mutual collision control;

- inverse-time generation, to have total control over the heads movement dynamics.

With the DDX Optimizer you obtain a considerable time saving, generating movements as much as possible tangent, not too wide and without collision, avoiding the classic junctions, characterized by large safety distances and axis unwinding.