XFactory

Take Back Your Control

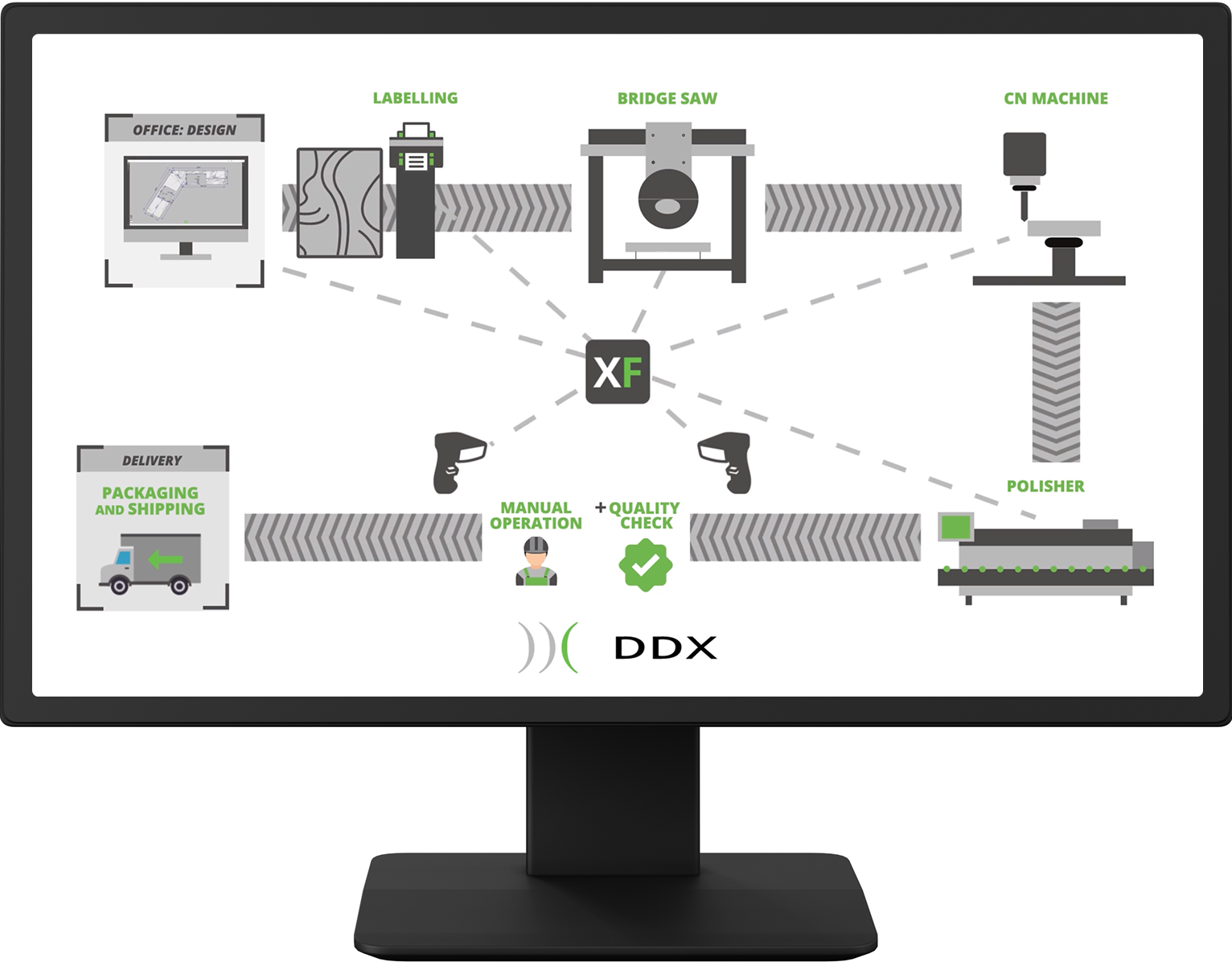

XFactory is the DDX software designed for production management. This web-based system allows you to monitor your order status at each workstation. It also displays data related to production times and cycles.

You can access XFactory wherever you are, using any type of browser.

XFactory’s Dual Soul

XFactory Manager

This is a complete solution that manages data exchange with multiple CNC machining centers and/or workstations.

XFactory Light

With this software, you can streamline your production cycle through data exchange with a single workstation—whether it’s a CNC machine or a manual station.

Our MES software is a solution that adapts to the needs of small and medium-sized enterprises, as well as more structured production facilities.

The constant communication between XFactory Light and XFactory Manager ensures that all stations involved in the plant’s processes are continuously monitored, enabling the optimization of the production cycle.

Want to learn more about XFactory?

XFactory Functionalities

Which are the features that make XFactory the perfect MES software for your business? Let’s discover them.

Piece Tracking

Depending on the machine manufacturer and model, we have implemented various communication mechanisms. In this way, XFactory can help you trace a piece on the CNC and monitor the progress of your order.

Warehouse Management

You can check the list of raw materials, along with the corresponding material you need to retrieve from the warehouse to carry out a specific job.

Warehouse Management

You can check the list of raw materials, along with the corresponding material you need to retrieve from the warehouse to carry out a specific job.

Processing Management

You can take a look at the list of operations to be performed on each component of the order. Additionally, you can verify the piece disposition on the machine.

Production Time Management

In XFactory’s “Job Execution”, you can monitor the execution time of the processed piece on the machine. Once the operation is complete, the following data will be saved:

- the date;

- the start and end time of the process;

- the total execution time.

Production Time Management

In XFactory’s “Job Execution”, you can monitor the execution time of the processed piece on the machine. Once the operation is complete, the following data will be saved:

- the date;

- the start and end time of the process;

- the total execution time.

Order Management

XFactory is fully integrated with our software. You can send your job order directly from our tools, or you can create it manually by associating your ISO files with third-party software.

Role Management

Once authenticated via reader (barcode, QR Code, RFID, etc.) or by entering login credentials, the operator confirms the assigned activities at the station they are working on. The goal is to define the runtime status and task monitoring.

Role Management

Once authenticated via reader (barcode, QR Code, RFID, etc.) or by entering login credentials, the operator confirms the assigned activities at the station they are working on. The goal is to define the runtime status and task monitoring.

Label Printing

Thanks to this feature of our MES software, you can print labels directly, creating your own custom layouts.

You can use any printer compatible with Windows systems.

Statistics

Thanks to integration with Microsoft Power BI, XFactory allows you to view production statistics using real-time data collected from each station, whether manual or CNC. The strength of this feature lies in the customization of the layout to highlight the most relevant data.

Statistics

Thanks to integration with Microsoft Power BI, XFactory allows you to view production statistics using real-time data collected from each station, whether manual or CNC. The strength of this feature lies in the customization of the layout to highlight the most relevant data.

How to Manage your Production Cycle with XFactory

Whether you manufacture kitchen countertops or cabinets, XFactory helps you monitor every stage of the process in real time. From labeling to shipping, our software is a flexible solution that adapts to your plant and production type.

Why choose DDX?

We develop CAD/CAM software designed to handle various types of materials.

We offer solutions to the leading players in both the national and international markets.

We design modular software that is compatible with major CNC machining centers.

Do you need more information?

Would you like to receive further details about our software solutions?

Do you need more information?

Support request

Technical support ticket