Everything You Need in One Software

Composite Materials

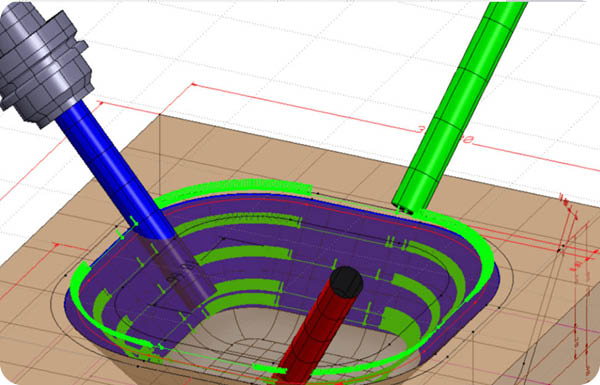

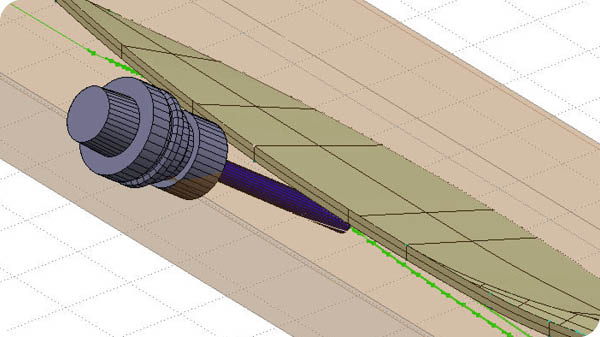

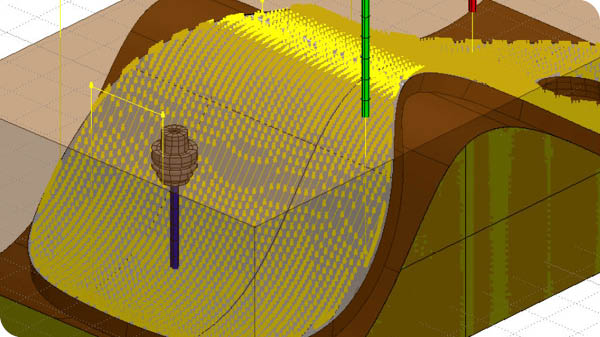

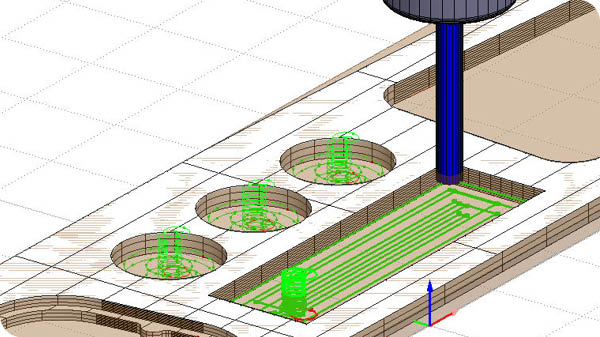

3-, 4-, and 5-axis Machining

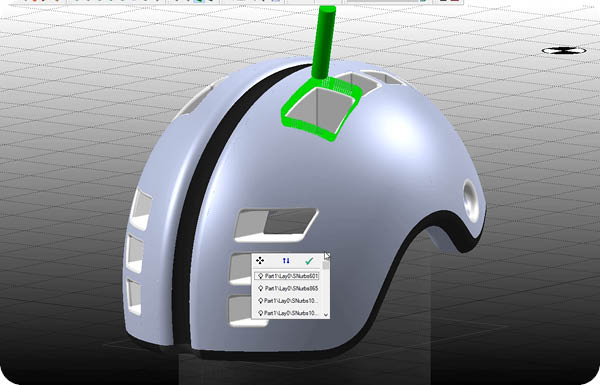

3D Modeling

Working Table Disposition

Toolpath optimization

Time and cost estimation

Design And Process Plastic, Aluminum, Light Alloys And Composite Materials

Whether you are into prototyping or large-scale production, XCAM provides you the perfect tools for the plastic industry.

Enhance the quality as well as the efficiency of your business and succeed in managing your projects with an innovative and intuitive software for composite materials.

XCAM – The DDX Software for the Most Demanding Challenges

Made With XCAM

Screenshots

Plugin

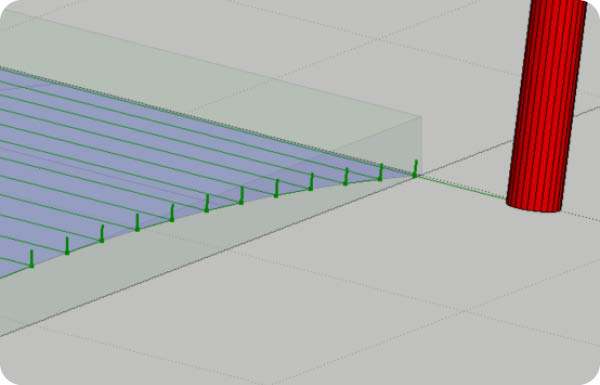

NestingReduce production time and cut costs with Nesting. Optimize the layout of parts on the workspace sheet and save material. |

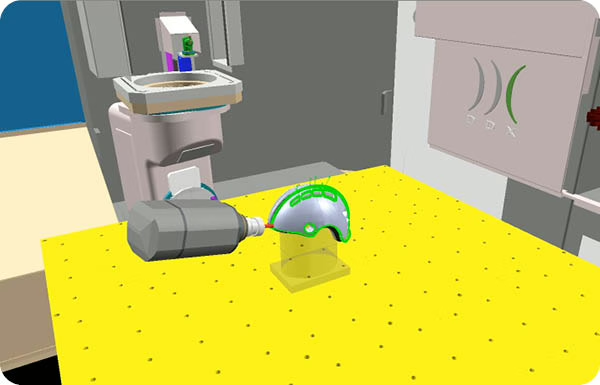

PowerSIMSimulate operations and visualize your CNC machine. With the "Collision Control" module, avoid potential collisions between tools or parts of your machine. |

XFactoryMonitor, track, document, and control the production process of your products with XFactory. Increase your plant's profitability with a dynamic and comprehensive MES. |

Automatic CAMAutomatically apply operations to your project based on specific rules and automate the data processing (DXF files). |

Automatic DispositionAutomate tool setup calculation and improve the workpiece holding on the machine by optimizing the size and positioning of the suction cups, while avoiding through operations. |

Automatic executionCreate a custom processing workflow for your designs: from applying operations to generating machine code. |

One Solution Partner: Related Products

Why choose DDX?

We develop CAD/CAM software designed to handle various types of materials.

We offer solutions to the leading players in both the national and international markets.

We design modular software that is compatible with major CNC machining centers.

Do you need more information?

Would you like to receive further details about our software solutions?

Do you need more information?

Support request

Technical support ticket