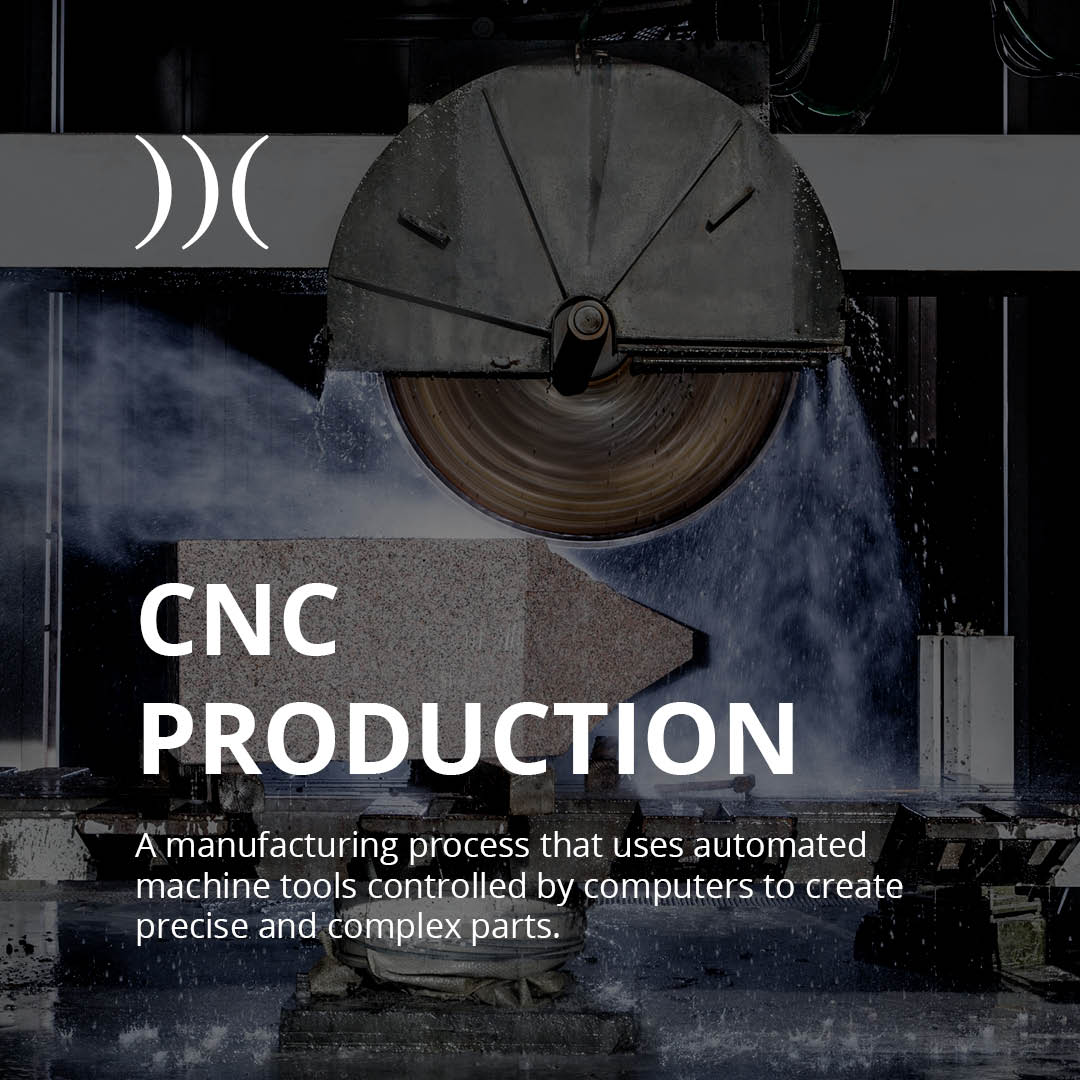

CNC production has revolutionized the stone processing industry, transforming the way companies handle challenges of precision, speed, and material optimization. Today, relying on CNC machines for marble integrated with innovative CAD/CAM software has become essential to ensure both quality and competitiveness.

At DDX, we stand out as a reliable technology partner, offering cutting-edge solutions such as EasySTONE®. Our stone processing software has been designed to simplify and optimize CNC production, turning your design into a finished product in just a few clicks.

What is CNC Production and How Does It Apply to Marble and Granite?

Compared to traditional stone processing methods, CNC production is far more efficient for those seeking high-quality results in a short time. Using a subtractive technology, CNC machines operate with optimized toolpaths directly generated by CAD/CAM software.

Let’s take a look at the main advantages of CNC production for marble and stone.

- Precision and repeatability: CNC machines enable controlled movements on multiple axes, ensuring tight tolerances even for the most complex projects.

- Speed and productivity: The mechanized process speeds up operations that would take much longer to perform manually. In addition, 3D simulation displays the final result before machining begins, leading to significant cost reduction.

- Complex shapes: Curves, 3D reliefs, decorative engravings, custom countertops, and profiled edges are easier to handle thanks to direct software control and optimized tool sets. The 3D tool visualization allows to simulate material removal, enabling the precise creation of even the most complex shapes with maximum precision.

- Reduced waste and enhanced safety: CAM programming optimizes the use of marble or granite slabs, significantly reducing waste.

EasySTONE® is the right solution for your CNC production.

The Challenges of CNC Production for Marble and Granite

Marble and granite processing requires advanced technological solutions because of the heterogeneous properties of these natural materials.

Their variable hardness, irregular veining, and porosity make both roughing and finishing operations more complex. In such cases, accuracy is the key: from design to cutting and polishing, the CNC production process must be flawless to avoid defects or excessive waste.

Another aspect not to be underestimated is time management. A poorly structured workflow, frequent setup changes, tool selection, and manual adjustments can slow down the entire process. This affects not only overall plant performance but also the sustainability of your CNC production.

This is where CAD/CAM software becomes essential. Only with advanced tools, you can define optimized toolpaths, preview stone cutting operations in 3D, and coordinate each stage of production. The result is a smoother, more efficient workflow.

Discover how EasySTONE® supports stone cutting and processing with CNC machines.

Why Choose Our EasySTONE® Software?

EasySTONE® provides a single work environment where you can manage every stage of CNC production, from design to machine code generation.

Why should you choose EasySTONE®? Let us explain.

- You can import files in all major CAD formats available on the market. Thanks to its parametric graphic engine, you can design any object you need in just a few clicks.

- The Nesting module allows to optimize production while minimizing material waste.

- With the integrated simulation engine, you can preview CNC machining directly on the workpiece, ensuring reliable results and preventing collisions.

- EasySTONE® allows you to manage multiple CNC machines for marble processing within a single production line.

Want to see EasySTONE® in action?